How I found out about Omnia

Hello, my name is Carina and I come from Mainz, Germany. I am currently doing an apprenticeship as a construction draughtswoman in Wiesbaden at Julius Berger International GmbH. In the period from 21.08.2023 to 08.09.2023 I had the opportunity to complete an Erasmus+ internship at Omnia. I became aware of the Erasmus+ program at vocational school. My interest was aroused by a presentation of the education institution. My goal was to visit a modern and progressive country. I came across Finland, or more precisely Omnia. Here I got my desired insight into new techniques. I learned how to use the 3D printer and the laser printer.

Planing and design

My task was to fill a free green space with meeting rooms, saunas and a leisure area according to my ideas.

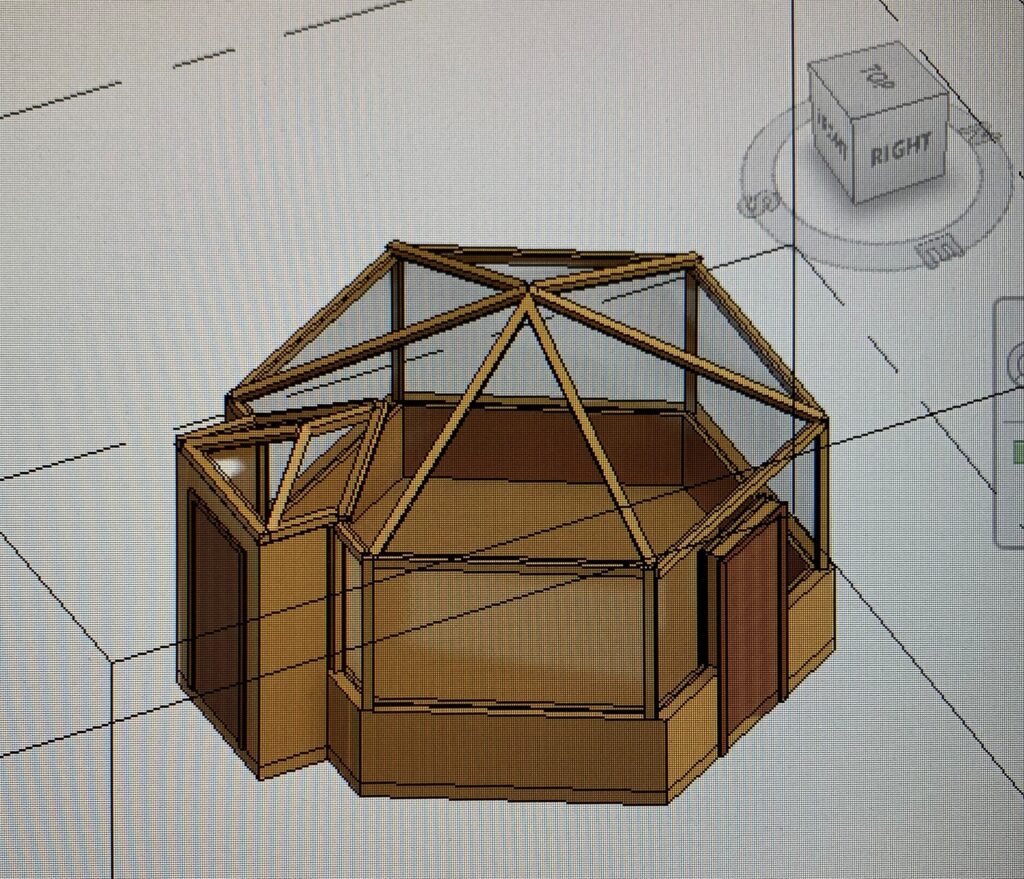

In the first week, I started by measuring the area. I made a sketch of the area to get a feel for the size of the space. I had a rough idea of my design, and the next step was to implement it in Revit. After drawing the floor plan, I started modelling the individual rooms. In the second week, I completed my planning in the vocational school.

3D modelling and printing

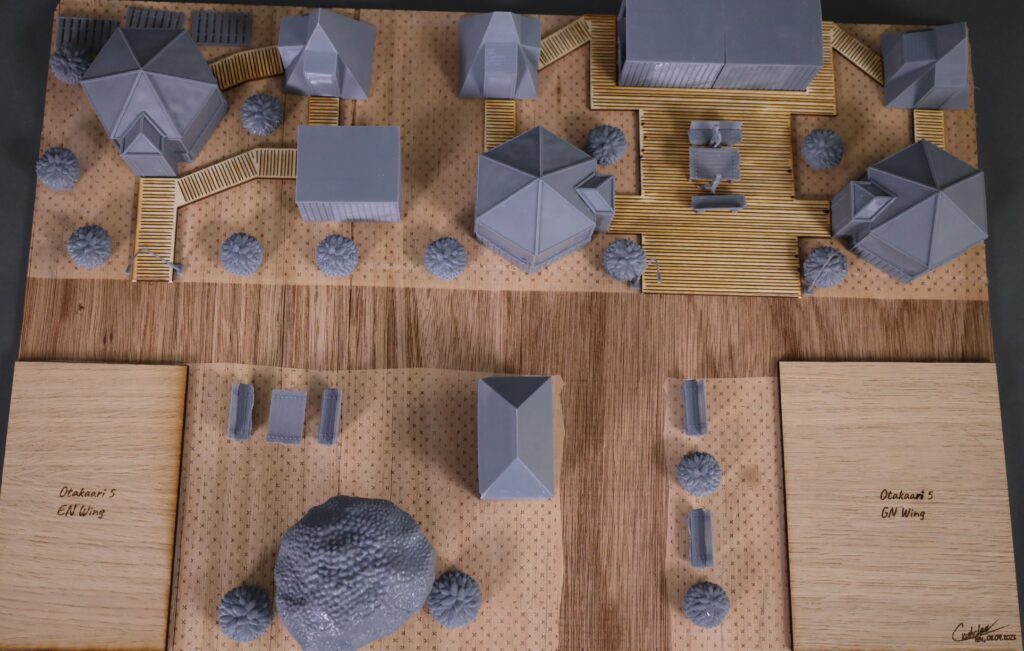

In the Makerspace, I first got to know the 3D printer and made a test print, which failed. Little by little I printed out my models, which worked quite well. To make the model more vivid, I also printed out pre-modelled trees, bushes and seating. While waiting for the next finished print, I removed the support strands from the already finished models. This sometimes requires a lot of fine-tuning. Last week I started to finish my 3D model with the laser printer. I created a terrace and planned the course of paths and lawns in Illustrator.

Laser

In the last two days, I got to know the laser cutter, among other things. In Illustrator, Siim and I drew the outlines of the terraces, the paths and the lawn. After I set all the settings correctly, we sent it to the printer one by one. The last step was to cut out the wooden panels into their correct shape. I glued the terrace and the buildings onto the surface of the engraved wooden sheet.

Traditional modeling often requires new materials, contributing to waste and resource depletion. Carina’s approach, however, utilizes laser engraving to etch intricate designs onto scrap wood pieces. This not only showcases technology’s capabilities but also promotes sustainability by conserving forests and reducing waste.Carina’s laser-engraved models serve as educational tools, demonstrating the value of recycling and creativity in design.

Siim Saar, host of Omnia Makerspace

Summary

My time here has been very enriching as I have learned many new techniques. I have met many lovely people here who were always open to questions. I am very grateful for the experience and to be able to say that I was able to create my own microcosm.